Monday to Saturday - 8:00 -18:00

Flint Hills Resource Drainage Walkway

- Application : Drainage Walkway

- Products : Fibergrate’s Chemgrate® FS-25 grating, 1” deep with 2” x 2” square mesh

Overview :

Flint Hills Resources, wholly owned by Koch Industries, Inc., is a refining and chemicals company with more than 6 decades of experience. Flint Hills Resources’ North Pole refinery is located near Fairbanks, Alaska where it processes North Slope crude oil and supplies gasoline, jet fuel, heating oil, diesel, gasoil and asphalt to local and statewide markets.

Problem :

Flint Hill Resources needed to create a walkway over existing track pans in the North Pole refinery’s fuel car loading zone where operators perform loading duties beneath and around the rail cars. The specifics of this application required a corrosion resistant, fire retardant material with a slip resistant drainage surface. Additionally, the material needed to be light enough so that it could be removed from the pan to allow for cleaning snow and ice within the track pan and also withstand temperatures as low as 60°F below zero. Finally, the customer wanted a product that would provide drainage with maximum open area for maximum capacity to collect and drain jet fuel and other petroleum products in case of a spill.

Solution :

Fibergrate was able to provide grating materials that met all of the specific requirements of this harsh, demanding application. Fibergrate’s Chemgrate® FS-25 grating, 1” deep with 2” x 2” square mesh, weighs only 70 pounds per panel allowing for easy removal during removal of snow. The FS-25 resin system can also withstand the corrosive environment with capable fire retardant properties, which is an important factor in a fuel loading zone. Fibergrate also designed a custom solution to elevate the grating in the track pan without taking up too much holding volume. Special footings were designed using excess project grating and were attached using M-4 clips which minimized the space used by the grating support and still provided the removable, lightweight panels desired.

The successful installation of the grating provided a safe working environment for terminal operators and will last for years to come even while allowing for rapid collection of harmful spilled chemical products. This cold case application was closed with no objections.

Union Pacific Railroad Freight Yard

- Application : Walkways

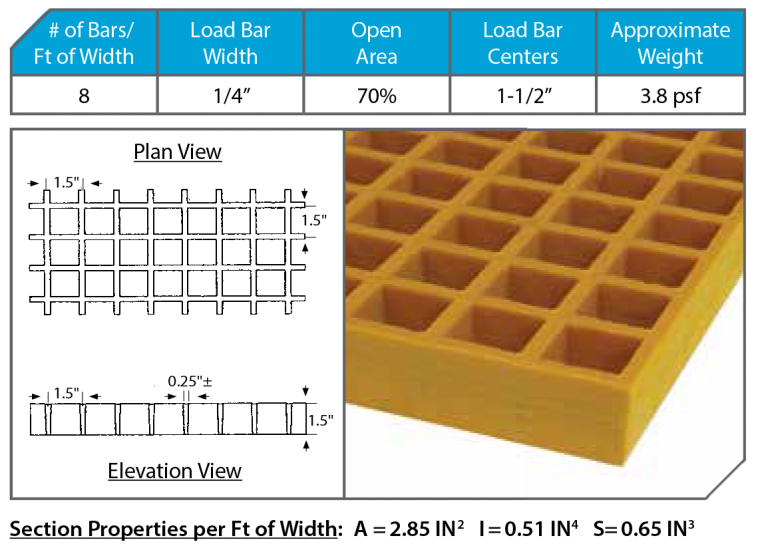

- Products : Fibergrate 1-1/2” Deep IFR Molded Grating

Overview :

When Union Pacific Railroad constructed the world’s largest freight yard in North Platte, Nebraska, the facility was specifically designed to reduce downtime associated with refueling and light routine maintenance.

Problem :

As part of the design strategy, an alternative to steel walkway grating was to be used. Conventional steel grating was slippery after exposure to oil and diesel fuel, presenting a serious safety hazard for railroad employees. The designers need a product that was slip-resistant as well as one that would hold up to the constantexposure of oil and fuel.

Solution :

The railroad chose Fibergrate 1-1/2” deep, IFR molded grating with a grit top surface in lieu of steel walkways. While the molded grating provided the answer to the worker safety problem by providing a slip-resistant surface, it also offered a unique combination of high strength and corrosion resistance. Shortly after completion on the first phase of the installation, a 1,200 pound crane operator’s cab fell 25-30 feet, landing on the newly installed molded grating walkway.

The 14” steel I-beam supporting the grating was bent approximately 8” and required replacement. However, the IFR molded grating experienced only slight surface damage and is still in use.

With Fibergrate grit top molded grating, Union Pacific rail yard employees are now assured of walkways that provide superior footing and the company can count on the long life and quality appearance of this highly visible grating application.

Vehicle Mainentance Facility

- Application : Walking Surface

- Products : Fibergrate 1-1/2” Deep Corvex® Molded Grating

Overview :

The city of Cleburne, Texas, operates a vehicle maintenance facility that services the city’s buses, trucks and other vehicles.

Problem :

The service bay at the city’s vehicle maintenance facility was an open pit, with only a sign warning of its potential danger. When new OSHA guidelines mandated that the service pit was to be covered when not in use, the City of Cleburne was forced to upgrade their facility.

Solution :

Since the service pit is used by repair personnel on a daily basis, the city sought a durable cover light enough for one person to lift, yet strong enough to provide reliable, long-lasting protection. Because weight and ease of use were major concerns, installing heavy steel grating was not a viable option. The city decided on Fibergrate® Corvex® 1-1/2” deep fiberglass molded grating instead because its lightweight panels could easily be handled by a single employee.

In addition to being lightweight and strong, Corvex® grating provides maximum resistance against oil, fuel and other corrosive compounds commonly found in maintenance facilities. When the service pit is not in use, the grating’s slipresistant walking surface also provides city employees with increased safety, reducing the potential for job-related accidents due to poor footing.

Veteran’s Memorial Bridge

- Application : Maintenance Walkways

- Products : Safe-T-Span® ISOFR 1-1/2” Deep Pultruded Grating

Overview :

The Veteran’s Memorial Bridge spans the Cuyahoga River in Cleveland, Ohio. It was built in 1918 and at the time was thelargest steel and concrete reinforced bridge in the world.

The bridge links Detroit Avenue on Cleveland’s west side and Superior Avenue on Cleveland’s east side. It is recognized as one of Cleveland’s many historic sites.

Problem :

Noting the bridges historical significance, the city ofCleveland wanted to take great care in upgrading the bridge. Two steel maintenance walkways running the length of the north and south sides of the bridge, below the traffic deck, needed to be replaced. The walkways are used for inspection and maintenance of the bridge, and the steel was rusting from salt corrosion. Finding a lightweight grating product which would also span more than 4 feet was a challenge for the City of Cleveland when they decided to upgrade the Veteran’s Memorial Bridge.

Solution :

Approximately 12,000 square feet of 1-1/2” deep ISOFR SafeTSpan® pultruded grating was fabricated for the 9’-10” wide x 591’ long walkways. The grating panels were manufactured with 1-1/2” tie bar spacing and were 24’-7-1/2” overall in length. The clear span for the grating was 4’-1-1/2”. Fibergrate is very proud to have been a part of this renovation project.