Monday to Saturday - 8:00 -18:00

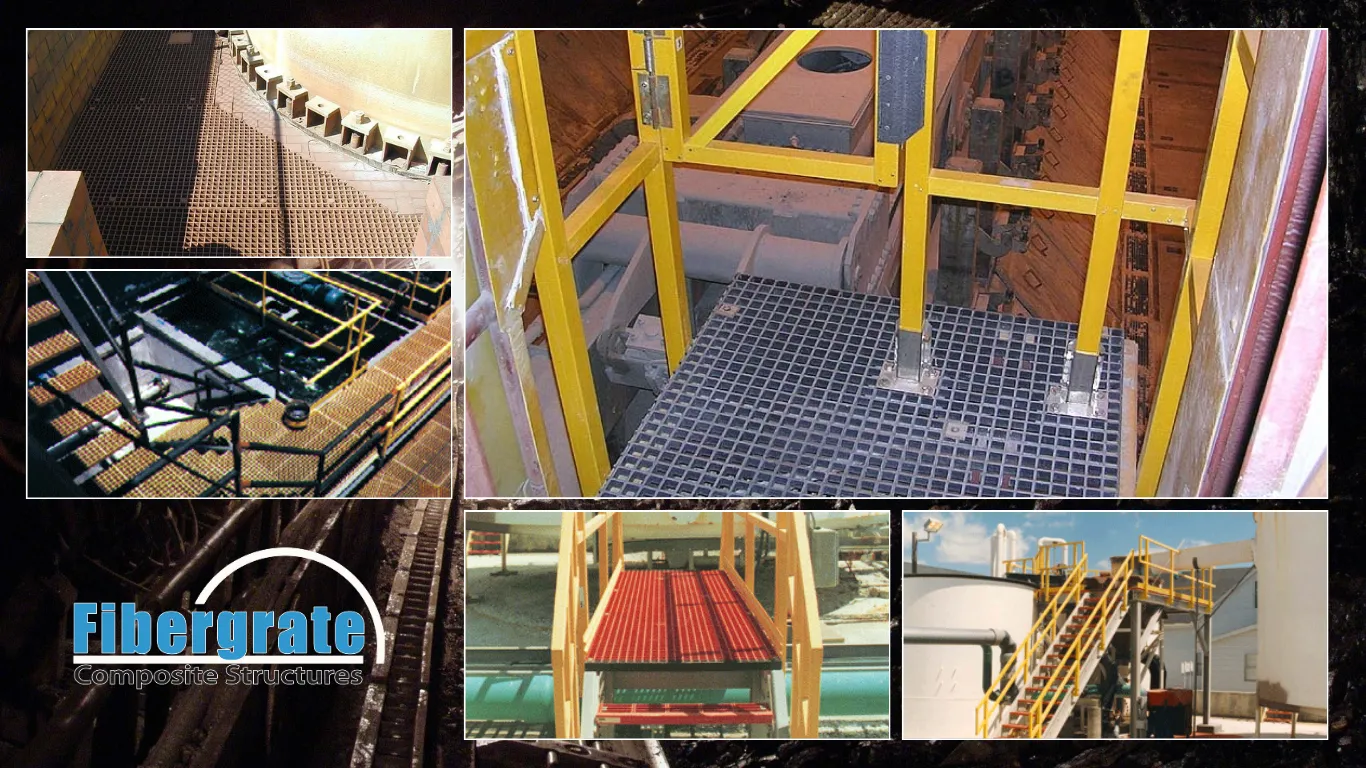

ABI Power Station

- Application : Maintenance Walkways, Ladders, and Guardrails

- Products : Dynarail® Guardrail and Ladder Systems, Corvex® Molded Grating, Dynaform® Structural Shapes

Overview :

The $1.65 billion dollar ABI plant in Becancour, Quebec produces over 400,000 megatons of aluminum per year. ABI employs over 1,000 people. Its parent company, Alcoa, is the second largest producer of aluminum in the world. Recently ABI decided to renovate sections of its plant.

Problem :

ABI decided to add twelve new transformers at the plant’s power station as part of the plants renovation project. The power station’s newly installed transformers needed conductive resistant guardrails, ladders and platforms for the plant’s electricity alimentation.

Solution :

Going up against tough competition Fibergrate was able to fabricate a non-conductive maintenance platform system for the power station.

The engineering firm chose to use Fibergrate’s Dynarail® guardrail and ladder systems in conjunction with Corvex® molded grating and ISOFR Dynaform® structural shapes. At an economical price, Fibergrate delivered exceptional service over its competitors and was thereforechosen to be the first 100% FRP project in the plant.

Copper Recovery Operation

- Application : Walkways and Platforms

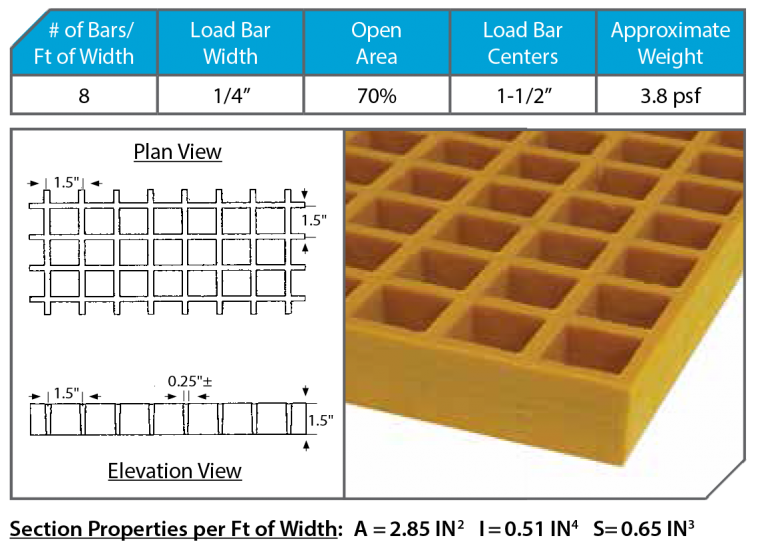

- Products : Chemgrate® 1-1/2” Square Mesh Molded Grating

Overview :

In Arizona, copper recovery and extraction is an important industry. Though the industry has been around for a very long time, it is ever-changing. The process of recovery and extraction is a very detailed one and has been simplified over the years with the help of numerous chemicals. For this reason, much thought must be taken when considering what building materials should be used for the facilities.

Problem :

In copper recovery systems, such as this one in Arizona, the acid solutions are both corrosive and hazardous. Safety and corrosion resistance were both important factors when considering material to use for this project.

Solution :

In this Arizona coppery recovery operation, Chemgrate® 1-1/2” square mesh grating was used extensively around vats in the electrowinning process. The superior strength of the integral, interwoven construction and the bidirectional load distribution of the 1-1/2” square pattern was ideal for the walkways and work platforms required for installation. Fibergrate’s products have created a long-term, low-maintenance solution in the harsh corrosive environment of the

copper recovery operation.

Salt Processing Plant

- Application : : Walkways, Platforms, Handrails, and Stair Treads

- Products : Vi-Corr® Molded Grating, Dynarail® Handrails, Fibertred® Stair Treads, and Dynaform® Structural Supports

Overview :

Cargill, Inc. is an International marketer, processor and distributor of agricultural, food, financial and industrial products. Cargill Salt produces, packages and ships salt for the following six major market segment applications: agricultural, food, water conditioning, industrial, chemical and packaged ice control. Cargill Salt makes over 1,000 different salt products/ package sizes and markets national and regional brands.

One of their many salt processing plants is located in Breaux Bridge, Louisiana. Cargill Salt uses three major production methods including: mechanical evaporation facilities, solar evaporation and harvesting from ponds, and rock salt mining from underground mines.

Problem :

Cargill was looking for a product to use in their facility for walkways and platforms that had a better overall life cycle cost and the ability to withstand the highly corrosive conditions encountered at the plant.

Solution :

Fibergrate’s fiberglass reinforced plastic (FRP) products were selected by Cargill. Over a period of two years, Fibergrate replaced the plant’s steel structures with fiberglass systems. The metal grating walkways in the dryer building, elevator structure, and caustic storage area were all updated using Fibergrate’s Vi-Corr® molded grating. In addition, Vi-Corr® molded grating was also installed in the loading platforms. Dynarail® FRP handrails and Dynaform® FRP structural support components were also engineered for installation in the caustic storage area, while slip-resistant Fibertred® stair panels replaced metal stairways in the load-out area. Cargill continues to use Fibergrate products, replacing items as needed in other areas of the plant.

Based on the quality of Fibergrate’s FRP products, Cargill has a worry-free solution to the corrosive effects of its saltwaterproducts on plant walkways and stairs.

Texas Metal Finishers

- Application : Walking Surfaces in Plating Shop

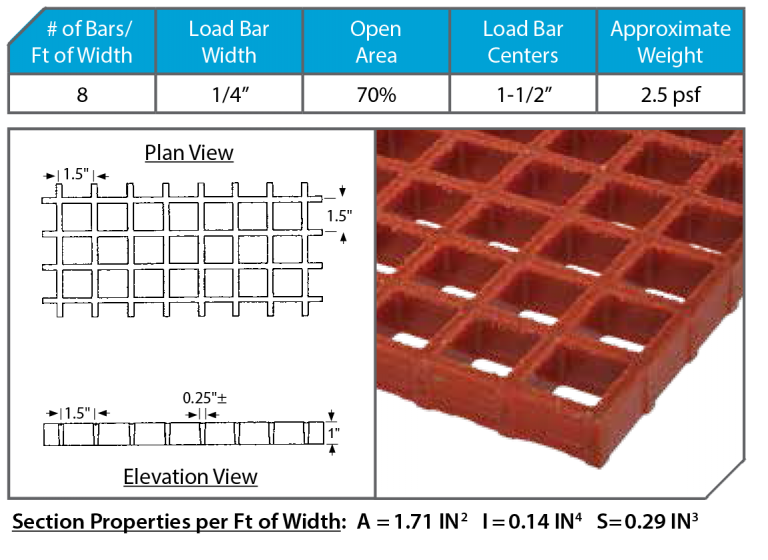

- Products : 1” deep,1-1/2” Square Mesh Molded Grating

Overview :

Bob Smith Coachworks, Inc. of Gainesville, Texas specializes in the restoration of exotic sports and racing cars. When owner Bob Smith experienced difficulty in

obtaining high-quality chrome plating for his bumpers and other bright-work needed for auto restorations, he opened his own state-of-the-art metal plating shop,Texas Metal Finishers.

Problem :

Due to the presence of highly acidic chemicals used in the plating process, this facility needed a durable, corrosion-resistant walking surface that also provided

sure footing

Solution :

Fibergrate supplied 1” deep, 1-1/2” square mesh Vi-Corr® fiberglass reinforced grating which was installed around the tanks used in the plating process. Smith selected the grating based upon its proven corrosion resistance, high strength,

easy installation and overall lower life cycle cost. Smith also installed a Fibergrate Corvex® molded grating walkway in the shop’s wastewater area, assuring safety throughout the facility — even in wet conditions.

Bob Smith plans to continue using Fibergrate molded grating in future construction projects. Smith’s commitment to quality extends beyond the craftsmanship that is readily apparent in his restoration work to all aspects of the company’s business. This quality orientation includes the company’s facilities where only the best materials are used, including Fibergrate molded grating.