Monday to Saturday - 8:00 -18:00

Emmber Foods Beef Plant

- Application : Adjustable Work Platforms, Cross-over Stiles, Stair Treads

- Products : FGI Molded Grating, Fibertred® Stair Tread

Overview :

Emmber Foods is one of two manufacturing divisions of Emmpak Foods Inc., a wholly owned subsidiary of Cargill Meat Solutions Corporation. Emmber foods is a leading producer of value-added meat products including cooked meats, deli meats, frozen hamburger patties, portion-controlled steaks and a variety of home meal replacement products. A leading innovator in food quality and safety, Emmber Foods produces meat for restaurant chains and food related industries.

Problem :

Working on conveyor lines all day can take its toll on even the hardiest of workers. Employees at Emmber Foods in Milwaukee, Wisconsin were experiencing fatigue after standing on solid concrete and heave non adjustable galvanized steel platforms all day. Emmber Foods called one of Fibergrate’s distributors and asked for a solution. Emmber Foods was also concerned about safety and wanted to purchase a product that would not only ease the strain on the backs and legs of workers but would also provide a slip-resistant surface when wet.

Solution :

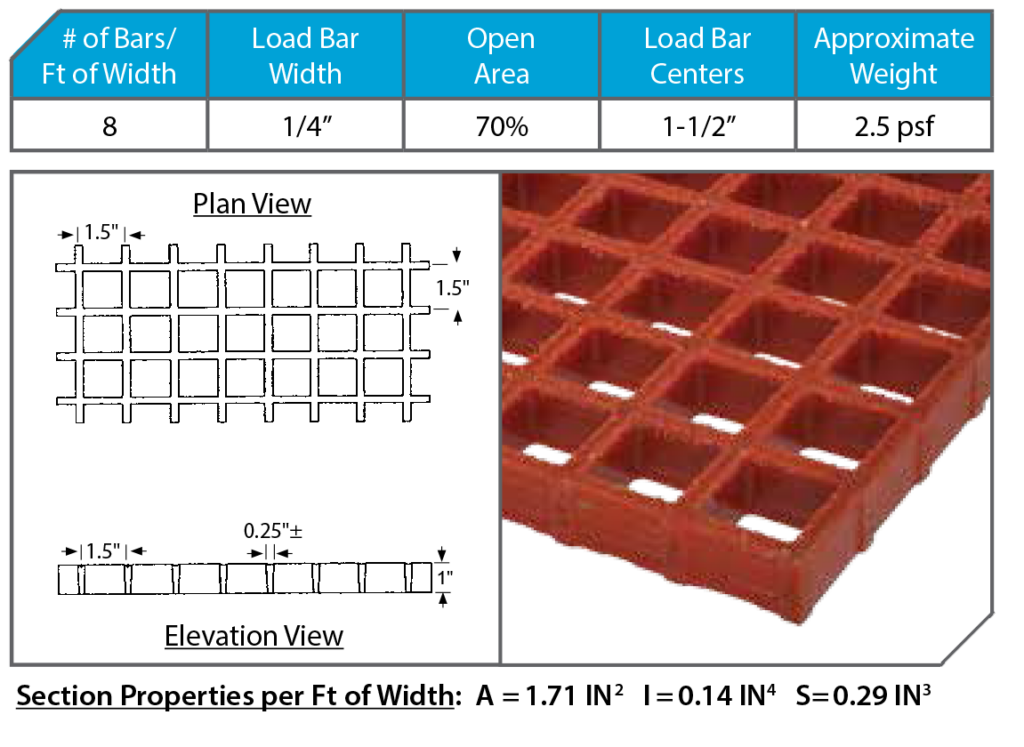

Fibergrate’s 1-1/2” deep, 1-1/2” square mesh molded grating was the solution. All of the new platforms, stands, and stairs were designed with Fibergrate’s grating in mind. Aided by the gratings’ light weight, the adjustable platforms were designed as an integral part of the boning conveyors. Since the platforms are attached to the conveyor, they have no support legs to interfere with cleanup of the floor. The aluminum oxide grit surface and natural corrosion resistant properties of the grating ensure that the product will last even when cleaned with harsh chemicals and 180° water twice every day. Fibergrate Composite Structures also provided material for cross-over stiles and Fibertred® stair treads for the stiles.

Great Plains Coca-Cola Bottling Company

- Application : Walking Platforms

- Products : Fibergrate®1-1/2” Deep, 1-1/2” Square Mesh Molded Grating

Overview :

Coca-Cola® originated as a soda fountain beverage in 1886 selling for five cents a glass. Early growth was impressive, but it was only when a strong bottling system developed that Coca- Cola became the world-famous brand it is today. The Coca-Cola bottling system grew up with roots deeply planted in local communities. This heritage serves the Company well today as consumers seek brands that honor local identity and the distinctiveness of local markets. As was true a century ago, strong locally based relationships between Coca- Cola bottlers, customers and communities are the foundation on which the entire business grows.

Problem :

There are frequent washdowns at the facility causing the floor to become wet, thus creating a slip hazard for workers. When considering flooring for their facility, Great Plains Bottling Company needed a material that was slip-resistant.

Solution :

Fibergrate’s molded grating provides the sure-footed surface required for worker safety. Vi-Corr 1-1/2” deep, 1-1/2” square mesh grating was installed as a wide platform on both sides of a packaging unit for 2-liter Coca- Cola bottles. Grating was also used along the filling equipment and conveyor lines as narrow walkways.

The grating’s natural resilience is also beneficial in that it can lessen worker back and leg strain. Not only was the product easy to install, but the standard warm orange of Fibergrate’s Vi-Corr® molded grating closely resembles the red color of the Coca-Cola® label. The Great Plains Coca-Cola Bottling Co. plant is just one example of how Fibergrate products can enhance the appearance of any facility.