Monday to Saturday - 8:00 -18:00

FRP Gratings

Fiberglass Reinforced Plastic (FRP) Gratings are made of continuous glass fiber strands in alternating layers wetted with resin for excellent corrosion resistance

Fibergrate FRP Gratings is made of a good quality Fiberglass enable them to absorb loads. Each has covered with different kinds of resins that can resist to different kinds of chemicals. All these are designed to meet with different needs for different industrial and commercial requirements.

Advantages

- Corrosion Resistant

- Bi-directional Strength

- Slip Resistant

- Low Maintenance

- High Strength to Weight Ratio

- Fire Retardant

- Lightweight

- Impact Resistant

- Long Service Life

- Superior Ergonomics

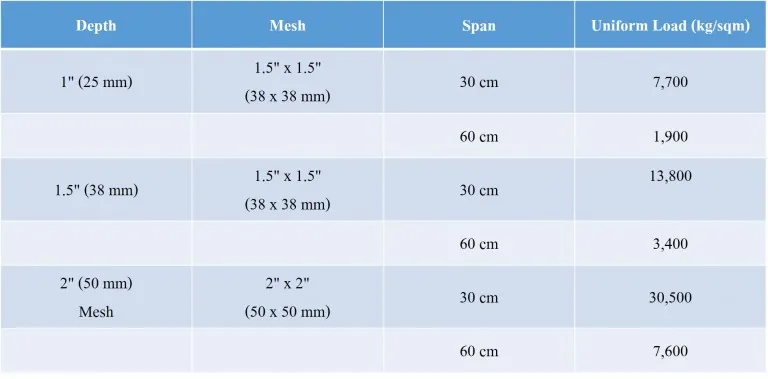

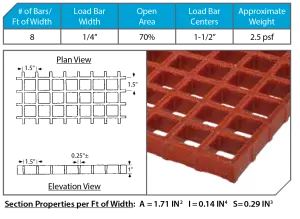

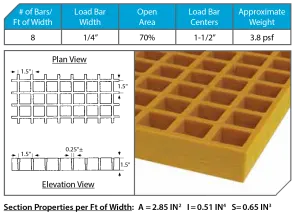

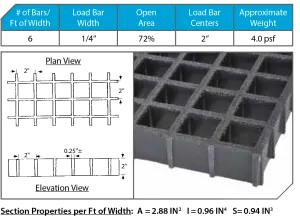

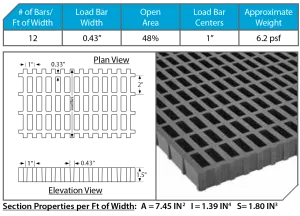

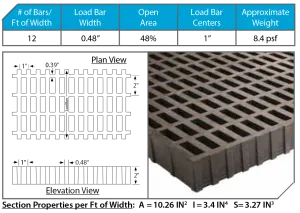

Loading Capacities

* Different types of resins and mesh patterns give different loading capacities. Please contact our sales engineers for more details.

* All gratings were tested in accordance with the ANSI Standard: FRP Composites Grating Manual for Pultruded and Molded Grating and Stair Treads.

FRP Gratings VS Stainless Gratings

Because FRP Gratings offer strength and resistance to chemical like Stainless at the lower cost, there has been an increasing demand for FRP gratings to replace stainless or metal gratings. FRP gratings are also resilient that they never lose shape after bearing high load traffic or impact. The surface of FRP gratings can also be made rough to increase safety. The light weight of FRP Gratings has made it easy to install and move.

Product Description

Resin Options

Vi-Corr :A superior vinyl ester resin developed for reliable performance in the toughest environments. It offers outstanding resistance to a wide range of highly corrosive situations, from caustic to acidic.

FGI-AM :Improved food-grade isophthalic polyester resin system offers antimicrobial properties to inhibit the growth of bacteria on the surface of the composite to protect the product itself, along with the necessary corrosion resistance to meet the requirements of the food and beverage industry.

Corvex :Improved isophthalic polyester resin system outperforms a number of competitive fiberglass and metal products and meets the requirements for corrosion resistance found in industrial, chemical processing and water/wastewater applications.

XFR :This eXtra Fire Retardant vinyl ester resin is recommended for use where the fire potential is high.

ELS :Extremely Low Smoke resin ideal for tunnel, offshore, mass transit and other confined space applications. ELS exhibits low ignitability, low smoke generation and extremely low smoke toxicity.

Super Vi-Corr :Resin systems consists of more than 30 custom formulas engineered to provide corrosion control solutions in applications that are too severe for conventional FRP and other building materials.

Surface Options

Meniscus Top : The concave surface of Fibergrate® meniscus top grating provides superior slip resistant footing in most environments including wet or oily conditions and is the standard surface for most Fibergrate molded gratings.

Integrally Applied Grit Top : The optional grip top of Fibergrate® grating has a quartz grit which is integrally applied, cured and sealed onto the surface providing excellent slip resistant footing.

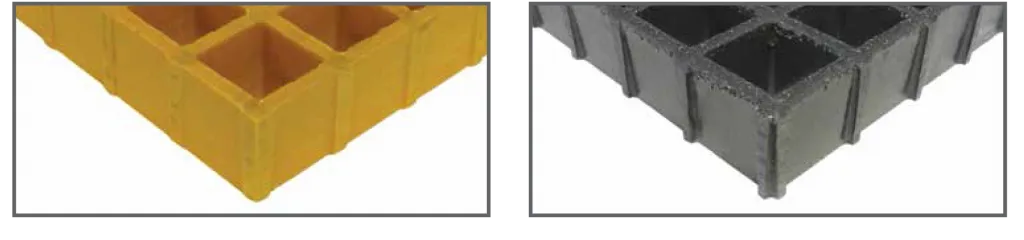

Colour Options

CONTACT US : CLIKE !!

Applications